| TECHNICAL DATA | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|||||||||

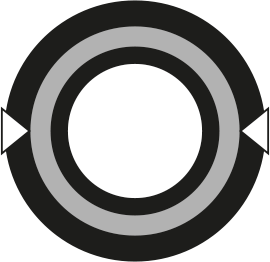

| PART REF. | HOSE SIZE | R.O.D | O.D | MAX. W.P | BURST | MIN. BEND | WEIGHT | FITTINGS | |||||||||

| DN | dash | inch | mm | inch | mm | inch | bar | psi | bar | psi | mm | inch | g/m | lb/ft | Std 1 | Std 2 | |

| H11022019* | 19 | -12 | 3/4” | 26.9 | 1.06 | 32.3 | 1.27 | 207 | 3,000 | 828 | 12,000 | 180 | 7.09 | 1,288 | 0.87 | OPK-12 | – |

| H11022025* | 25 | -16 | 1” | 34.1 | 1.34 | 40.1 | 1.58 | 207 | 3,000 | 828 | 12,000 | 230 | 9.06 | 1,876 | 1.26 | OPK-16 | – |

KEY FEATURES

• Highly robust hose structure

• Thermal insulation of the hose with a special cover material

• Long lasting resistance of the cover layer

• Cover has flame retardant properties

• High ozone and weather resistance

APPLICATIONS & FLUIDS

• Hydraulics: designed for use in areas where the continuous hydraulic function is required to drive the emergency systems (industrial, marine, off-shore and refineries, defence, mining)

• Flexible hose for hydraulic systems of Blow Out Preventer control lines on drilling rigs

• Mineral oils, glycols and polyglycols, mineral oils in aqueous emulsion

CONTINUOUS SERVICE TEMPERATURE RANGE

-40 °C, -40 °F

121 °C, 250 °F

TUBE

High grade NBR oil resistant synthetic rubber

REINFORCEMENT

Four high tensile steel spirals

COVER

Red insulant and flame retardant synthetic rubber

APPLICABLE SPECS

API 16D Fire Test (pr.10.1.2), ISO 18752-C

TYPE APPROVALS

DNV-GL; CU-TR; MSHA; API 16D Fire Test (DNV); LR; CCS; ABS

REMARKS

Refer to GoldenGuard assembling instructions and crimp chart for correct assembling (partial skive required)