| TECHNICAL DATA | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|||||||||

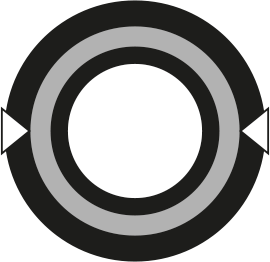

| PART REF. | HOSE SIZE | R.O.D | O.D | MAX. W.P | BURST | MIN. BEND | WEIGHT | FITTINGS | |||||||||

| DN | dash | inch | mm | inch | mm | inch | bar | psi | bar | psi | mm | inch | g/m | lb/ft | Std 1 | Std 2 | |

| H11020010* | 10 | -6 | 3/8” | 16.7 | 0.66 | 20.7 | 0.81 | 345 | 5,000 | 1,380 | 20,010 | 127 | 5.00 | 651 | 0.44 | MF+M00920-06 | OPK-06 |

| H11020012* | 12 | -8 | 1/2” | 20.1 | 0.79 | 24.1 | 0.95 | 345 | 5,000 | 1,380 | 20,010 | 150 | 5.91 | 820 | 0.55 | MF+M00910-08 | OPK-08 |

| H11020016* | 16 | -10 | 5/8” | 25.5 | 1.00 | 30.9 | 1.22 | 345 | 5,000 | 1,380 | 20,010 | 180 | 7.09 | 1,490 | 1.00 | IP+M01500-10 | – |

| H11020019* | 19 | -12 | 3/4” | 29.0 | 1.14 | 36.2 | 1.43 | 345 | 5,000 | 1,380 | 20,010 | 240 | 9.45 | 2,024 | 1.36 | IP+M01500-12 | SP+M05400-12 |

| H11020025* | 25 | -16 | 1” | 36.0 | 1.42 | 44.0 | 1.73 | 345 | 5,000 | 1,380 | 20,010 | 300 | 11.81 | 2,742 | 1.84 | IP+M01500-16 | SP+M05400-16 |

| H11020031* | 31 | -20 | 1.1/4” | 47.0 | 1.85 | 55.0 | 2.17 | 345 | 5,000 | 1,380 | 20,010 | 420 | 16.54 | 4,293 | 2.88 | IP+M01600-20 | SP+M05500-20 |

| H11020038* | 28 | -24 | 1.1/2” | 54.6 | 2.15 | 62.6 | 2.46 | 345 | 5,000 | 1,380 | 20,010 | 500 | 19.69 | 5,531 | 3.72 | IP+M01600-24 | SP+M05500-24 |

| H11020051* | 51 | -32 | 2” | 68.4 | 2.69 | 76.4 | 3.01 | 345 | 5,000 | 1,380 | 20,010 | 630 | 24.80 | 7,712 | 5.18 | IP+M01800-32 | SP+M05500-32 |

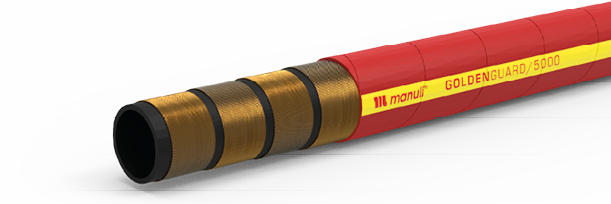

KEY FEATURES

• Highly robust hose structure

• Thermal insulation of the hose with a special cover material

• Long lasting resistance of the cover layer

• Cover has flame retardant properties

• High ozone and weather resistance

APPLICATIONS & FLUIDS

• Hydraulics: designed for use in areas where the continuous hydraulic function is required to drive the emergency systems (industrial, marine, off-shore and refineries, defence, mining)

• Flexible hose for hydraulic systems of Blow Out Preventer control lines on drilling rigs

• Mineral oils, glycols and polyglycols, mineral oils in aqueous emulsion

CONTINUOUS SERVICE TEMPERATURE RANGE

-40 °C, -40 °F

121 °C, 250 °F

TUBE

High grade NBR oil resistant synthetic rubber

REINFORCEMENT

Multiple plies of high tensile steel wire spirals (DN 16-25); 2 wire braids (DN 10-12)

COVER

Red insulant and flame retardant synthetic rubber

APPLICABLE SPECS

API 16D Fire Test (pr.10.1.2), DN 10-12: ISO 18752-A; DN 16-51: ISO 18752-C (STD2 fitting) and Type C “Plus” (STD1 fiting), ISO 3862 & SAE J517-100R13 performance

TYPE APPROVALS

DNV-GL; CU-TR; MSHA; API 16D Fire Test (DNV); LR; CCS; ABS

REMARKS

Refer to GoldenGuard assembling instructions and crimp chart for the use of accessories when required:

– STD1 fitting solution: Fire sleeve & metal sleeve over the fitting area required

– STD2 fitting solution: No accessories required

The STD1 fitting solution has been selected for the most demanding applications

DN 10 & 12: Max. continuous temperature 100 °C for these wire braided references