| TECHNICAL DATA | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|||||||||

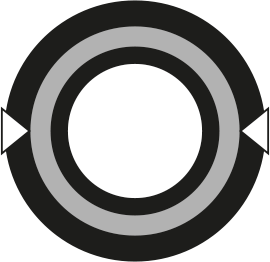

| PART REF. | HOSE SIZE | R.O.D | O.D | MAX. W.P | BURST | MIN. BEND | WEIGHT | FITTINGS | |||||||||

| DN | dash | inch | mm | inch | mm | inch | bar | psi | bar | psi | mm | inch | g/m | lb/ft | Std 1 | Std 2 | |

| H01139006* | 6 | -4 | 1/4" | 11.3 | 0.44 | 13.1 | 0.52 | 450 | 6,520 | 1,800 | 26,100 | 45 | 1.77 | 269 | 0.18 | MF+M03400-04 | – |

| H01139010* | 10 | -6 | 3/8" | 16.7 | 0.66 | 18.5 | 0.73 | 400 | 5,800 | 1,600 | 23,200 | 127 | 5.00 | 518 | 0.35 | MF+M00920-06 | OPK-06 |

| H01139012* | 12 | -8 | 1/2" | 20.1 | 0.79 | 22.1 | 0.87 | 362 | 5,250 | 1,450 | 21,030 | 150 | 5.91 | 683 | 0.46 | MF+M00910-08 | OPK-08 |

| H01139016* | 16 | -10 | 5/8" | 23.2 | 0.91 | 25.2 | 0.99 | 340 | 4,930 | 1,360 | 19,720 | 200 | 7.87 | 833 | 0.56 | MF+M00910-10 | OPK-10 |

| H01139019* | 19 | -12 | 3/4" | 27.1 | 1.07 | 29.3 | 1.15 | 310 | 4,490 | 1,240 | 17,980 | 230 | 9.06 | 1,034 | 0.69 | MF+M00930-12 | OPK-12 |

| H01139025* | 25 | -16 | 1" | 35.1 | 1.38 | 37.8 | 1.49 | 240 | 3,480 | 960 | 13,920 | 300 | 11.81 | 1,531 | 1.03 | MF+M00930-16 | OPK-16 |

| H01139032* | 31 | -20 | 1.1/4" | 44.5 | 1.75 | 47.2 | 1.86 | 175 | 2,530 | 700 | 10,150 | 380 | 14.96 | 2,055 | 1.38 | MF+M00920-20 | OPK-20 |

| H01139038* | 38 | -24 | 1.1/2" | 51.0 | 2.01 | 53.7 | 2.11 | 146 | 2,110 | 584 | 8,470 | 450 | 17.72 | 2,444 | 1.64 | MF+M00910-24 | – |

| H01139051* | 51 | -32 | 2” | 62.8 | 2.47 | 65.5 | 2.58 | 112 | 1,620 | 448 | 6,490 | 600 | 23.62 | 3,013 | 2.02 | MF+M00910-32 | – |

| H01139076* | 76 | -48 | 3" | 87.8 | 3.46 | 91.4 | 3.60 | 70 | 1,010 | 280 | 4,060 | 500 | 19.69 | 3,901 | 2.62 | MF+M03400-48 | – |

KEY FEATURES

• Superior pressure rating

• Superior abrasion resistance

• High ozone and weather resistance

• Flame resistance to a wide range of specs.

• Antistatic and anti-toxic cover

• Robustness thanks to skive fittings solution

APPLICATIONS & FLUIDS

• Hydraulics: high pressure lines with installation constraints in severe environmental conditions, specific installations with tough abrasion conditions, marine applications, underground and open pit mining

• Mineral oils, vegetable and rape seed oils, glycol and polyglycol based oils, synthetic ester based oils, oils in aqueous emulsion, water

CONTINUOUS SERVICE TEMPERATURE RANGE

-40 °C, -40 °F

100 °C, 212 °F

TUBE

Oil resistant synthetic rubber

REINFORCEMENT

Two high tensile steel braids

COVER

R.O.C.

Synthetic rubber with extreme abrasion and ozone resistance

APPLICABLE SPECS

Manuli® Design exceeds ISO 1436-2SN; EN 853-2SN; SAE J517 Type 100R2AT. Performance BCS 174; ISO 6805 Type 4

TYPE APPROVALS

CU-TR; MSHA