| TECHNICAL DATA | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

PROOF |

|

|

||||||

| PART REF. | HOSE TYPE | HOSE SIZE | MAX. W.P | BURST | TEST | FITTINGS | ACCESSORIES | |||||

| DN | dash | inch | bar | psi | bar | psi | bar | psi | Armour Guard | |||

| H01139010* | ROCKMASTER/2 PLUS SAW | 10 | -6 | 3/8” | 345 | 5,000 | 1,380 | 20,000 | 690 | 10,000 | MF+IM00920-06 | JP45G090280099 |

| H01139012* | ROCKMASTER/2 PLUS SAW | 12 | -8 | 1/2” | 345 | 5,000 | 1,380 | 20,000 | 690 | 10,000 | MF+IM00910-08 | JP45G090320099 |

| H10044016* | ROCKMASTER/4SH | 16 | -10 | 5/8” | 345 | 5,000 | 1,380 | 20,000 | 690 | 10,000 | IP+IM01500-10 | JP45G090400099 |

| H10035019* | ROCKMASTER/13 | 19 | -12 | 3/4” | 345 | 5,000 | 1,380 | 20,000 | 690 | 10,000 | IP+IM01500-12 | JP45G090450099 |

| H10035025* | ROCKMASTER/13 | 25 | -16 | 1” | 345 | 5,000 | 1,380 | 20,000 | 690 | 10,000 | IP+IM01500-16 | JP45G090500099 |

| H10035032* | ROCKMASTER/13 | 31 | -20 | 1.1/4” | 345 | 5,000 | 1,380 | 20,000 | 690 | 10,000 | IP+IM01600-20 | JP45G090650099 |

| H10035040* | ROCKMASTER/13 | 38 | -24 | 1.1/2” | 345 | 5,000 | 1,380 | 20,000 | 690 | 10,000 | IP+IM01600-24 | JP45G090750099 |

| H10035051* | ROCKMASTER/13 | 51 | -32 | 2” | 345 | 5,000 | 1,380 | 20,000 | 690 | 10,000 | IP+IM01800-32 | JP45G090900099 |

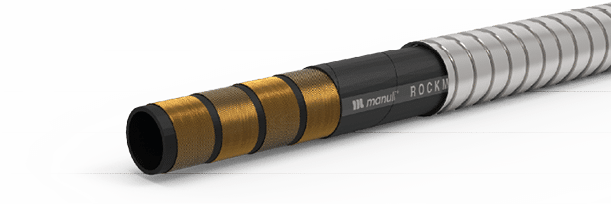

KEY FEATURES

• Highly robust hose structure

• Thermal insulation of the hose with a stainless steel armour cover

• Long lasting resistance of the cover layer

• Flame retardant properties

• High ozone and weather resistance

APPLICATIONS & FLUIDS

• Hydraulics: designed for use in areas where the continuous hydraulic function is required to drive the emergency systems (industrial, marine, off-shore and refineries, defence, mining)

• Flexible hose for hydraulic systems of Blow Out Preventer control lines on drilling rigs

• Mineral oils, glycol and polyglycol based oils, mineral oils in aqueous emulsion

CONTINUOUS SERVICE TEMPERATURE RANGE

-40 °C, -40 °F

100 °C, 212 °F (DN 10 & DN12); 121 °C, 250 °F (DN 16 – DN 51)

TUBE

High grade NBR oil resistant synthetic rubber

REINFORCEMENT

Two high tensile steel braids (DN 10-12); Multiple plies of high tensile steel spirals (DN 16-51)

COVER

STRONG – TYPE “SD”

Synthetic rubber with high abrasion, ozone, weather and heat resistance

APPLICABLE SPECS

API 16D Fire Test (pr.10.1.2);

ISO 18752-A (DN 10-12);

ISO 18752-C, ISO 3862, SAE J517 Type 100R13 performance (DN 16-51)

TYPE APPROVALS

DNV-GL; LR; API 16D Fire Test (DNV); ABS; CCS; CU-TR

| GOLDENARMOUR MAKE-UP | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

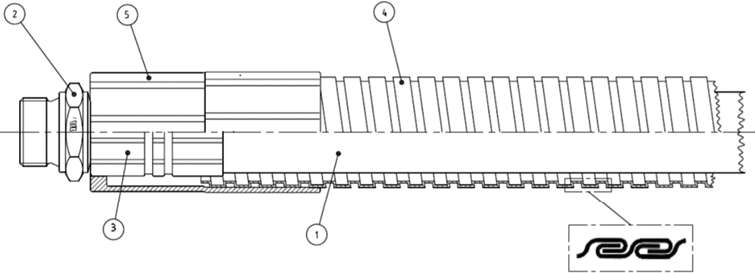

1. Hydraulic hose 2. Hydraulic MF2000 insert type, with additional tail o-ring only for IP fitting solution 3. Hydraulic MF2000 ferrule type 4. External flexible Metal Armour (interlocked flexible metal hose) 5. Metal Sleeve |

||||||||||||||||

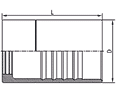

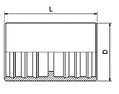

| ACCESSORIES TECHNICAL DATA | |||||||||||||||||

|

|

|

|

|

|

|

|||||||||||

| ARMOUR PART REF. |

TO SUIT HOSE SIZE |

ARMOUR SIZE |

MIN. BEND | WEIGHT | METAL SLEEVE | ARMOUR JOINT | |||||||||||

| d | D | PART REF. | D | L | PART REF. | D | L | ||||||||||

| DN | dash | inch | mm | inch | mm | inch | mm | inch | g/m | lb/ft | mm | mm | mm | mm | |||

| JP45G090280099 | 10 | -6 | 3/8” | 25 | 1” | 32.0 | 1.26 | 127 | 5.00 | 565 | 0.38 | IO82110-06GA | 40.5 | 60 | IO84210-06 | 40.5 | 65 |

| JP45G090320099 | 12 | -8 | 1/2” | 31 | 1.1/4” | 36.5 | 1.44 | 150 | 5.91 | 703 | 0.47 | IO82110-08GA | 46.8 | 75 | IO84210-08 | 46.8 | 65 |

| JP45G090400099 | 16 | -10 | 5/8” | 38 | 1.1/2” | 44.5 | 1.75 | 180 | 7.09 | 939 | 0.63 | IO82110-10GA | 53.2 | 90 | IO84210-10 | 53.2 | 65 |

| JP45G090450099 | 19 | -12 | 3/4” | 46 | 1.3/4” | 51.0 | 2.01 | 240 | 9.45 | 1,118 | 0.75 | IO82110-12GA | 59.5 | 105 | IO84210-12 | 59.5 | 70 |

| JP45G090500099 | 25 | -16 | 1” | 51 | 2” | 57.5 | 2.26 | 300 | 11.81 | 1,301 | 0.87 | IO82110-16GA | 66.0 | 120 | IO84210-16 | 66.0 | 75 |

| JP45G090650099 | 31 | -20 | 1.1/4” | 63 | 2.1/2” | 70.0 | 2.76 | 420 | 16.54 | 1,636 | 1.10 | IO82110-20GA | 78.6 | 135 | IO84210-20 | 78.6 | 95 |

| JP45G090750099 | 38 | -24 | 1.1/2” | 76 | 3” | 82.5 | 3.27 | 500 | 19.69 | 1,920 | 1.29 | IO82110-24GA | 91.5 | 150 | IO84210-24 | 91.5 | 105 |

| JP45G090900099 | 51 | -32 | 2” | 89 | 3.1/2” | 96.0 | 3.78 | 630 | 24.80 | 2,386 | 1.60 | IO82110-32GA | 106.5 | 165 | IO84210-32 | 106.5 | 115 |

| ARMOUR JOINING PROCEDURE | |||||||||||||||||

| Individual pieces of the GoldenArmour metal sleeve can be joined using a dedicated Armour Joint. The procedure for joining the pieces of flexible armour is as follows: | |||||||||||||||||

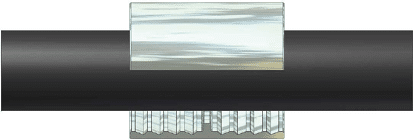

| 1. Slide the Armour Joint onto the hose. |  |

||||||||||||||||

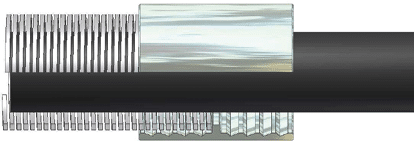

| 2. Insert the first piece of flexible armour into the Armour Joint until it reaches the internal stop. |  |

||||||||||||||||

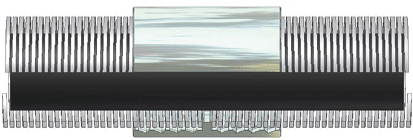

| 3. Insert the second piece of flexible armour into the other side of the Armour Joint until it also reaches the internal stop |  |

||||||||||||||||