| TECHNICAL DATA | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|||||||||

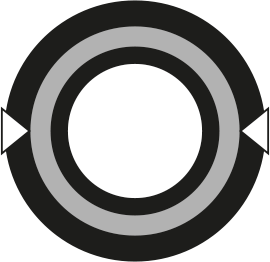

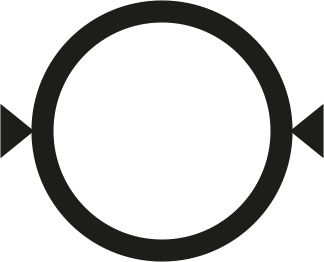

| PART REF. | HOSE SIZE | R.O.D | O.D | MAX. W.P | BURST | MIN. BEND | WEIGHT | FITTINGS | |||||||||

| DN | dash | inch | mm | inch | mm | inch | bar | psi | bar | psi | mm | inch | g/m | lb/ft | Std 1 | Std 2 | |

| H10125031* | 31 | -20 | 1,1/4” | 47.7 | 1.88 | 50.9 | 2.00 | 420 | 6,090 | 1,680 | 24,360 | 400 | 15.75 | 4,175 | 2.81 | IP+M01850-20 | – |

| H10125038* | 38 | -24 | 1.1/2” | 55.2 | 2.17 | 58.7 | 2.31 | 420 | 6,090 | 1,680 | 24,360 | 450 | 17.72 | 5,195 | 3.49 | IS+M02700-24 | – |

| H10125051* | 51 | -32 | 2” | 68.9 | 2.71 | 72.4 | 2.85 | 420 | 6,090 | 1,680 | 24,360 | 500 | 19.69 | 7,265 | 4.88 | IS+M02700-32 | – |

KEY FEATURES

• Robustness and durability – longer than 1 year on “hump hose” applications

• Bend radius exceeds standard requirements by -30% to -50%

• Good flexibility across the whole temperature range

• Easy mounting in any installation

• High impulse resistance according to ISO 18752

• Isobaric pressure rating for easy selection and product management

APPLICATIONS & FLUIDS

• High pressure power lines for general hydraulics

• Heavy duty power lines

• Hump hoses on giant excavators

• Long durability due to special tube compound

• Applications with long assemblies with self-standing capacity

• Applications with installation constraints (short assemblies, compact spaces, low bend radii etc.)

• Mineral oils, vegetable oils and synthetic ester based oils (up to 100°C/212°F), glycols and polyglycols, mineral oils in aqueous emulsion, water

CONTINUOUS SERVICE TEMPERATURE RANGE

-46 °C, -50 °F

135 °C, 275 °F

TUBE

Oil resistant synthetic rubber

REINFORCEMENT

Six high tensile steel spirals

COVER

STRONG – TYPE “SC”

Synthetic rubber with high abrasion, ozone, weather and heat resistance and an extended operational temperature range

APPLICABLE SPECS

ISO 18752-D Ext., exceeds SAE J517 R15

TYPE APPROVALS

MSHA; CU-TR

REMARKS

Hercules/HT is enhanced by new HSSL heat shrinkable sleeves (optional). These heat shrinkable sleeves protect the ferrule from dirt inclusion and moisture ingression under the ferrule. Sleeves are made with heat shrinkable material, which is self-extinguishing and provides low voltage electrical insulation, provide the best possible protection with high abrasion resistance.