| TECHNICAL DATA | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|||||||||

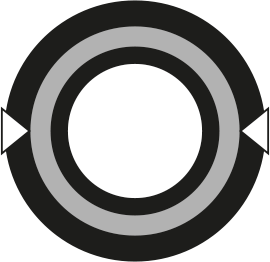

| PART REF. | HOSE SIZE | R.O.D | O.D | MAX. W.P | BURST | MIN. BEND | WEIGHT | FITTINGS | |||||||||

| DN | dash | inch | mm | inch | mm | inch | bar | psi | bar | psi | mm | inch | g/m | lb/ft | Std 1 | Std 2 | |

| H10116063* | 63 | -40 | 2.1/2" | 80.6 | 3.17 | 84.8 | 3.33 | 350 | 5,070 | 1,400 | 20,300 | 800 | 31.49 | 8,105 | 5.45 | IP+M01810-40 | – |

| H10116076* | 76 | – 48 | 3" | 89.0 | 3.5 | 92.1 | 3.62 | 165 | 2,390 | 700 | 10,152 | 660 | 25.98 | 6,060 | 4.07 | IP + M01500-48 | – |

KEY FEATURES

• Very high flow rates in high pressure

• Extreme robustness of the hose structures

• Hose compact dimensions

• Approved with severe fatigue tests

• Superior abrasion resistance

• High ozone and weather resistance

• Flame retardant (MSHA) and antistatic properties

• Biological and mineral oils compatibility

• Crimped InterLock Plus fitting structure

APPLICATIONS & FLUIDS

• Hydraulics: heavy duty power lines in China coal mines, hydrostatic transmissions in severe environmental conditions, specific installations with tough abrasion conditions, underground and open pit mining.

• Mineral oils, vegetable oils and synthetic ester based oils (up to 100°C/212°F), glycols and polyglycols, mineral oils in aqueous emulsion, water

CONTINUOUS SERVICE TEMPERATURE RANGE

-40 °C, -40 °F

121 °C, 250 °F

TUBE

Oil resistant synthetic rubber

REINFORCEMENT

Six high tensile steel spirals

COVER

STRONG – TYPE “SC”

Synthetic rubber with high abrasion, ozone, weather and heat resistance and an extended operational temperature range

APPLICABLE SPECS

MT/T 98

TYPE APPROVALS

MA; MSHA; CU-TR

REMARKS

The brand of the hose reports Allowable Working Pressure (AWP) 50.0 MPa (500 bar), Safety Factor 2.8:1 according to the China Norm MT/T 98