| TECHNICAL DATA | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|||||||||

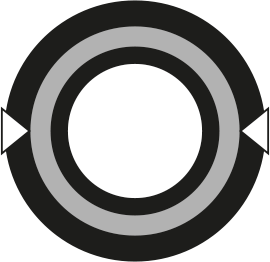

| PART REF. | HOSE SIZE | R.O.D | O.D | MAX. W.P | BURST | MIN. BEND | WEIGHT | FITTINGS | |||||||||

| DN | dash | inch | mm | inch | mm | inch | bar | psi | bar | psi | mm | inch | g/m | lb/ft | Std 1 | Std 2 | |

| H10118031* | 31 | -20 | 1.1/4” | 51.2 | 2.02 | 54.4 | 2.14 | 621 | 9,005 | 2,484 | 36,018 | 600 | 23.62 | 5,638 | 3.79 | IP+M01900-20 | – |

| H10118038* | 38 | -24 | 1.1/2” | 59.3 | 2.33 | 63.2 | 2.49 | 621 | 9,005 | 2,484 | 36,018 | 800 | 31.50 | 7,100 | 4.77 | IS+M02900-24 | – |

KEY FEATURES

• Extremely robust structure for liquid concrete high pressure pumping, with safety factor 4:1

• Double-skive reliable fittings, also available in stainless steel

• Approved for very high pressure hydraulics with ISO 6803 fatigue test (200,000 cycles, T=100°C, WP)

APPLICATIONS & FLUIDS

• Liquid concrete, bentonite, for jet grouting (very high pressure)

• Hydraulic oils (heavy duty, high pressure)

• Water-based hydraulic oils, water

CONTINUOUS SERVICE TEMPERATURE RANGE

-40 °C, -40 °F

100 °C, 212 °F

TUBE

Oil resistant synthetic rubber

REINFORCEMENT

Multiple high tensile wire spirals

COVER

STRONG – TYPE “SC”

Synthetic rubber with high abrasion, ozone, weather and heat resistance and an extended operational temperature range

APPLICABLE SPECS

ISO 18752 Grade A Ext., EN 16228-6: safety factor 4:1

TYPE APPROVALS

MSHA; CU-TR