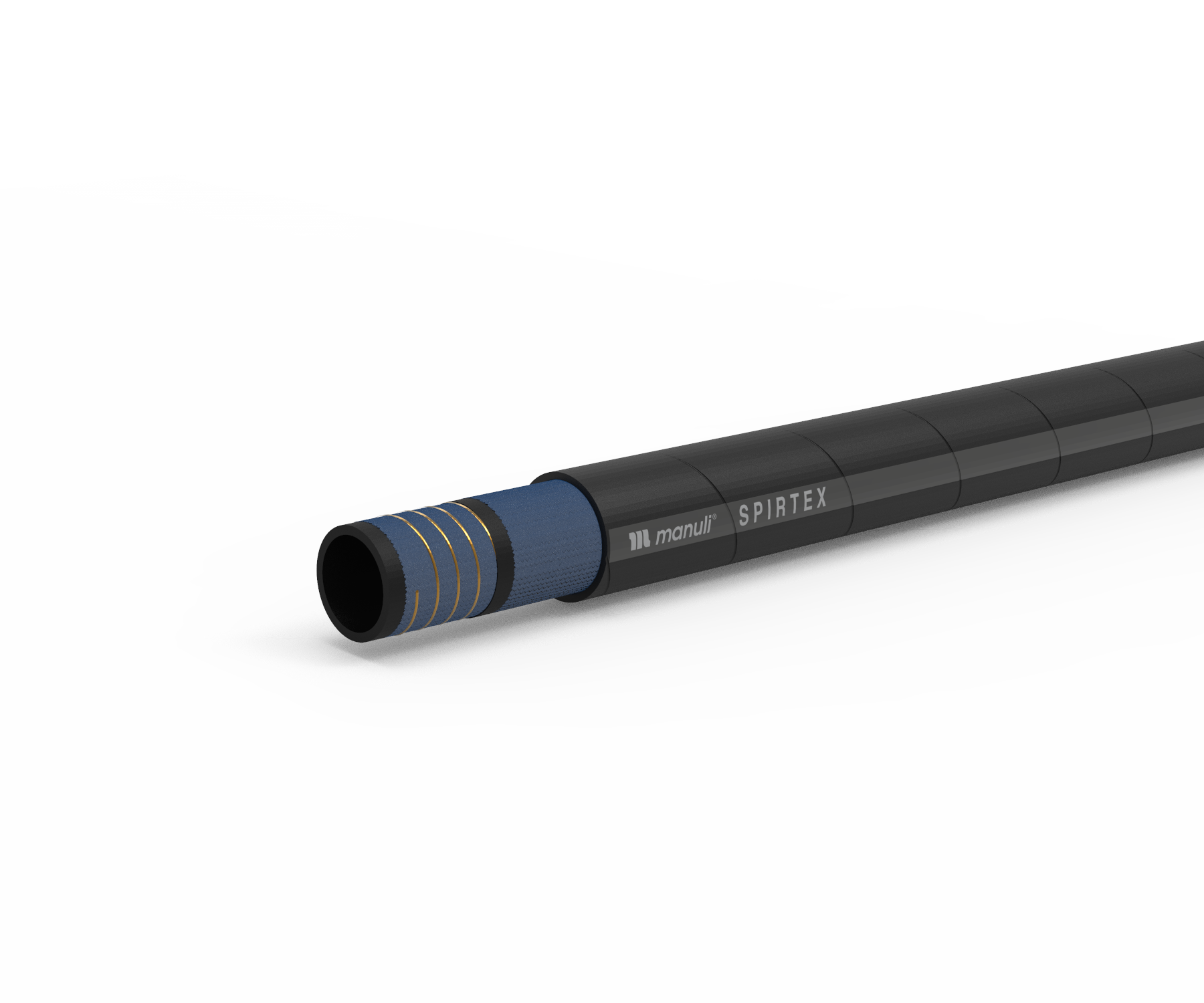

SPIRTEX

SAE 100 R4 SUCTION AND DELIVERY HOSE

KEY FEATURES

- Hardwall hose used for the suction and delivery of hydraulic oils

- High robustness of hose structure

- Long lasting in severe applications

- Resistance to Vacuum

- Improved minimum bend radius

- Max. length: 60m

- Hydraulics: suction lines, return lines

- Mineral oils, vegetable and rape seed oils, glycol and polyglycol based oils, synthetic ester based oils, oils in aqueous emulsion, water

CONTINUOUS SERVICE TEMPERATURE RANGE

-40 °C, -40 °F

100 °C, 212 °F

TUBE

NBR synthetic rubber

REINFORCEMENT

High tensile synthetic cord, helix body wire

COVER

Weather resistant synthetic rubber

APPLICABLE SPECS

SAE J517 100 R4, Manuli® Design; two-thirds the SAE J517

100R4 minimum bend radius

TYPE APPOVALS

CU-TR

DISCLAIMER:

We reserve the right to modify our products and/or related services and/or discontinue the manufacture and/or supply of any of the products and/or related services, without notice. This document supersedes all previous versions and previously issued documentation. The only official source of technical crimping parameters regarding our products is our Digital Crimp Tools. Printed copies are uncontrolled therefore, please be sure to use the latest versions of our Manuli Crimp App or Manuli Crimp Web Tool. Don’t mix and match: always use original hoses and fittings. For more information, see our ‘Safety Guide’.