| TECHNICAL DATA | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|||||||||

| PART REF. | HOSE SIZE | R.O.D | O.D | MAX. W.P | BURST | MIN. BEND | WEIGHT | FITTINGS | |||||||||

| DN | dash | inch | mm | inch | mm | inch | bar | psi | bar | psi | mm | inch | g/m | lb/ft | Std 1 | Std 2 | |

| H80023019* | 19 | – 12 | 3/4" | – | – | 30.4 | 1.19 | 21 | 300 | 84 | 1,218 | 62.0 | 2.44 | 560 | 0.38 | SR + D08100-12 | – |

| H80023025* | 25 | – 16 | 1" | – | – | 36.9 | 1.45 | 17 | 250 | 70 | 1,015 | 75.0 | 2.95 | 745 | 0.50 | SR + D08100-16 | – |

| H80023031* | 31 | – 20 | 1.1/4" | – | – | 43.9 | 1.72 | 14 | 200 | 56 | 812 | 100.0 | 3.93 | 850 | 0.57 | SR + D08100-20 | – |

| H80023038* | 38 | – 24 | 1.1/2" | – | – | 50.7 | 1.99 | 11 | 160 | 44 | 638 | 127.0 | 5.00 | 1,000 | 0.67 | SR + D08100-24 | – |

| H80023051* | 51 | – 32 | 2" | – | – | 63.4 | 2.49 | 7 | 100 | 28 | 406 | 150.0 | 5.90 | 1,414 | 0.95 | SR + D08100-32 | – |

| H80023063* | 63 | – 40 | 2.1/2" | – | – | 77.4 | 3.04 | 4 | 60 | 16 | 232 | 177.0 | 6.96 | 2,357 | 1.58 | SR + D08100-40 | – |

| H80023076* | 76 | – 48 | 3" | – | – | 89.4 | 3.51 | 4 | 60 | 16 | 232 | 230.0 | 9.05 | 2,712 | 1.82 | SR + D08100-48 | – |

| H80023089* | 89 | – 56 | 3.1/2" | – | – | 104.9 | 4.12 | 3 | 40 | 12 | 174 | 265.0 | 10.43 | 3,465 | 2.33 | SR + D08100-56 | – |

| H80023102* | 102 | – 64 | 4" | – | – | 116.4 | 4.58 | 3 | 40 | 12 | 174 | 305.0 | 12.00 | 3,832 | 2.57 | SR + D08100-64 | – |

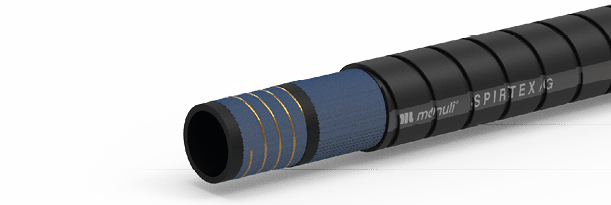

KEY FEATURES

• Hardwall hose used for the suction and delivery of hydraulic oils

• Flat corrugated (grooved) cover for improved flexibility and reduced bend radius (1/2 of SAE J517 100 R4)

• Long lasting in severe applications

• Resistance to Vacuum

• Max. length: 40m

APPLICATIONS & FLUIDS

• Hydraulics: suction lines, return lines

• Difficult installations with space constraints

• Mineral oils, vegetable and rape seed oils, glycol and polyglycol based oils, synthetic ester based oils, oils in aqueous emulsion, water

CONTINUOUS SERVICE TEMPERATURE RANGE

-40 °C, -40 °F

100 °C, 212 °F

TUBE

NBR synthetic rubber

REINFORCEMENT

High tensile synthetic cord, helix body wire

COVER

Weather resistant synthetic rubber, flat corrugated (grooved) cover style

APPLICABLE SPECS

Exceeds SAE J517 100 R4, Manuli® Design; half the SAE J517 100 R4 minimum bend radius

REMARKS

Working Pressure with Push-Lock fittings: DN 5, 6, 8, 10, 12, 16, 19, WP = 17 bar; DN 25, WP = 12 bar